DOLPHIN 275

Dolphin 275 Gallon Liquid Tote 48X40

Lapoint Packaging is now manufacturing our lightest liquid tote to date: the LP DOLPHIN. These well-positioned containers follow our hallmark pop-up design, and are the perfect solution for lighter, ambient temperature liquids.

DOLPHIN Liquid Totes are a greener alternative to rigid bottle-in-cage or corrugated IBCs.

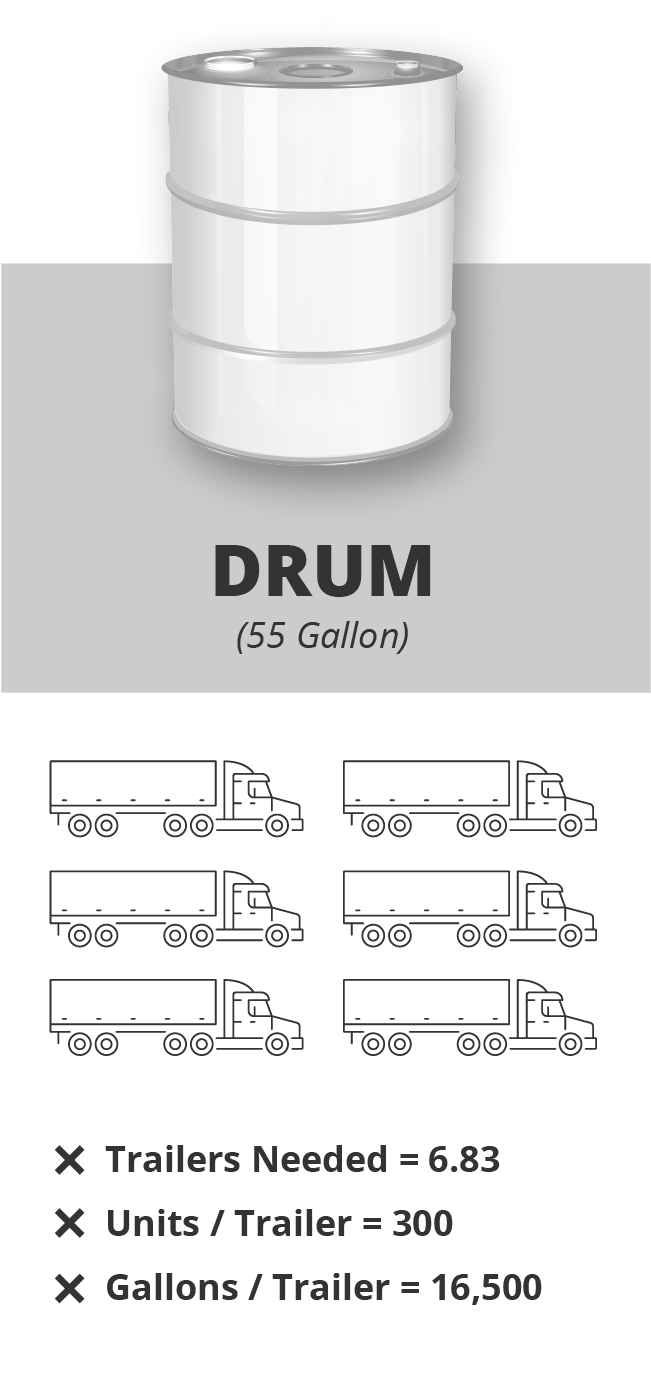

The DOLPHIN is also available in 110 and 220 gallon capacities, great alternatives to 55-gallon drums.

See your sales rep for additional information on Lapoint Packaging’s DOLPHIN, as well as our most popular ORCA, and heavy-duty MOBI containers, and be sure to click on the Specs and Benefits tabs below.

Dolphin 275 Gallon Specifications

Dimensions

OD: 46 3/8″L x 38″W x 40″H; ID: 43 1/4″L x 35 1/4″W x 40″H

Tare Weight of Tote + Cover

57 lbs / 26 kg

Tare Weight of Cassetted Liner

9 lbs / 4 kg

Pallet Size

48″ x 40″

Pallet Quantity

20

Truckload Quantity

357 Complete Units (tote, lid, liner in cassette)

Capacity

275 gal / 1041 ltr

Max Working Load

2400 lbs / 1089 kg

Stacking Limits

Up to 2-High

Liner

LLDPE 3-Ply in Loading Cassette

Fill and Decant Fitments

2″ / 2″

Dolphin 275 Gallon Benefits

- Skirted UV protected and water-resistant cover over open top tote offers easy access for drop-in liner cassette

- Woven recyclable PE exterior sheds splatters, is moisture and UV resistant and can be cleaned without damaging the core

- Pop-up composite body requires no additional assembly and takes only seconds to prepare for filling

- Move directly to your fill line up to 20 units at a time in a single stack – no pre-staging required

- Our direct-contact liquid liners are FDA/Kosher/Halal approved and IMS certified

- Compatible with automated filling equipment

- Available with or without bottom discharge valve for liquids or dry ingredients

ROI CALCULATOR

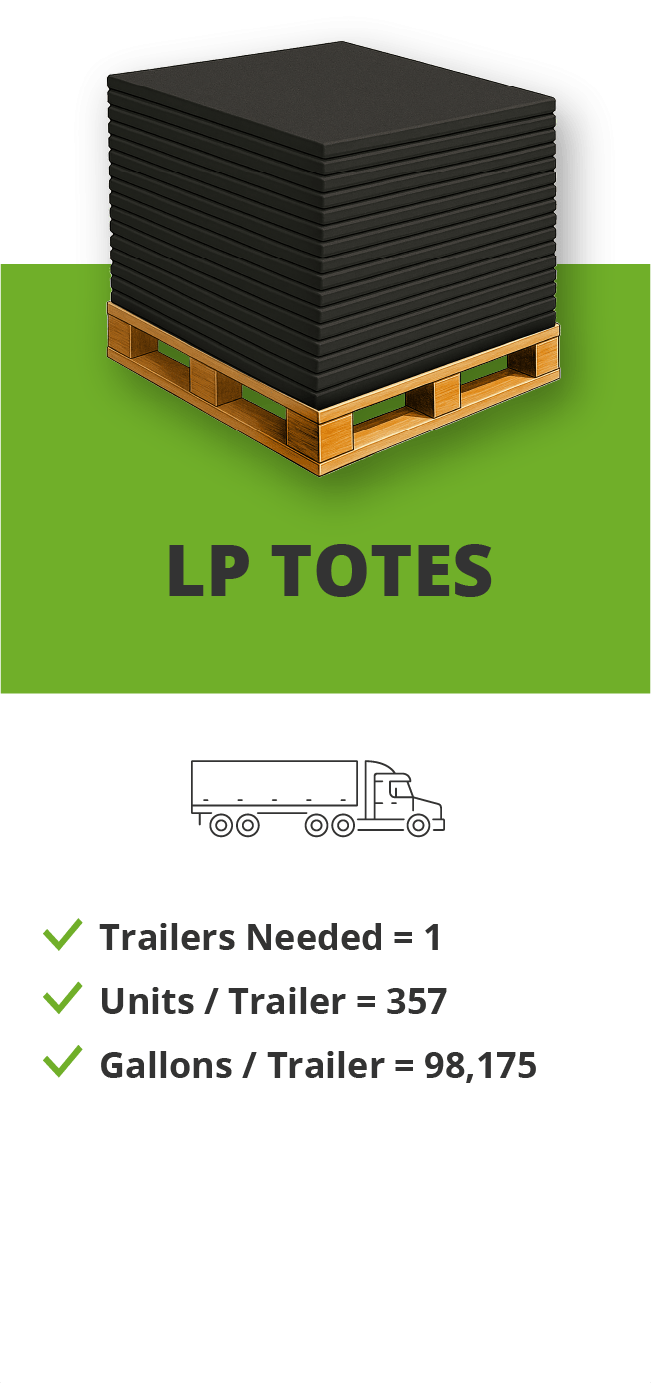

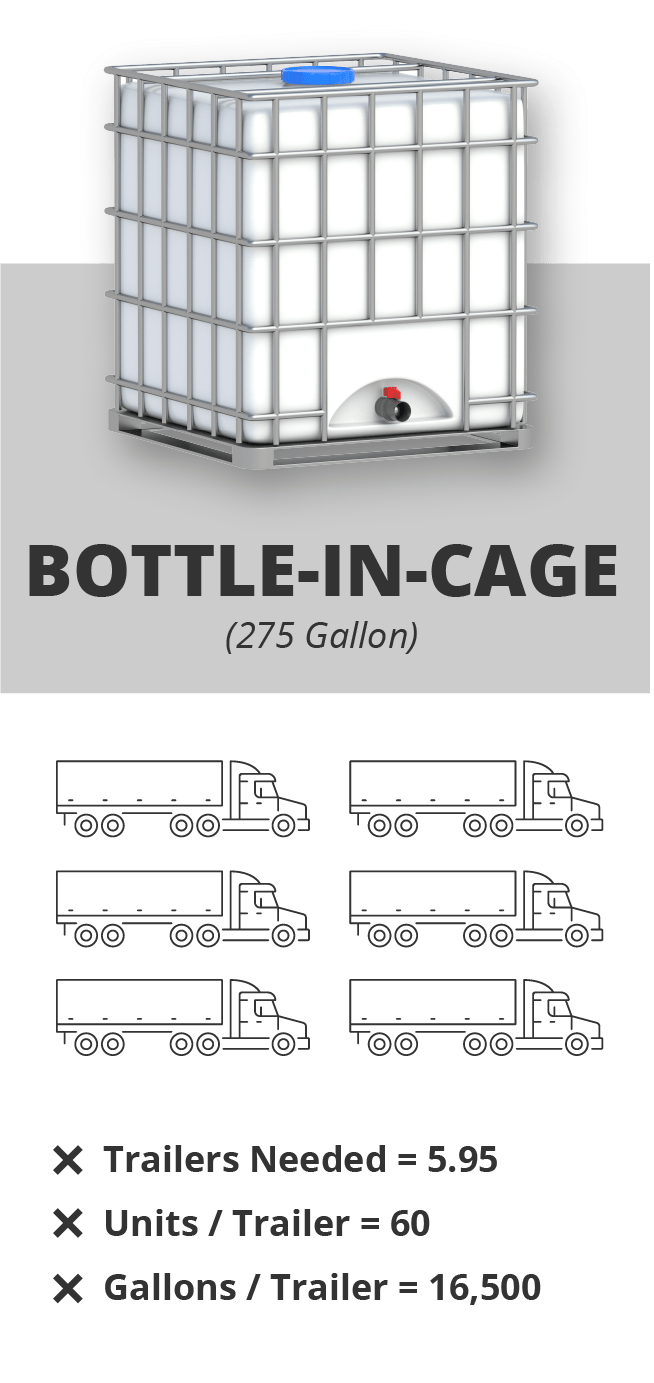

Inbound Freight Efficiency

Packgen’s LP TOTES allows you to get 5.95 times the inbound freight efficiency. See how much you can save on inbound freight by switching to PackGen’s LP Liquid Tote.

Results

PackGen LP Totes Required:

Competitor Trucks Required:

Annual Freight Savings:

CO₂ Reduction: